Technologies

Material Portfolio

At RAW, we specialize in 3D printing with a range of high-quality materials, including PP, PETG and HDPE.

Our material choice depends on the product type, the environment in which it will be used and specific

customer requirements. Below, you can learn more about how we select our materials, their advantages,

limitations, typical applications and examples.

Note: RAW does not print with

toxic materials, ensuring the safety of our team and minimizing harmful emissions into the environment.

Material properties

Our materials stand out

Read below to learn why.

Engineered for heavy use

Our fiber-reinforced plastics are chosen for their strength, flexibility and resilience under harsh conditions. This is ideal for maritime products, off-grid systems and both indoor and outdoor furniture.

Seamless bonding

We use high-precision 3D printing that ensures strong layer adhesion. This creates durable products with structural integrity that hold up over time and under pressure.

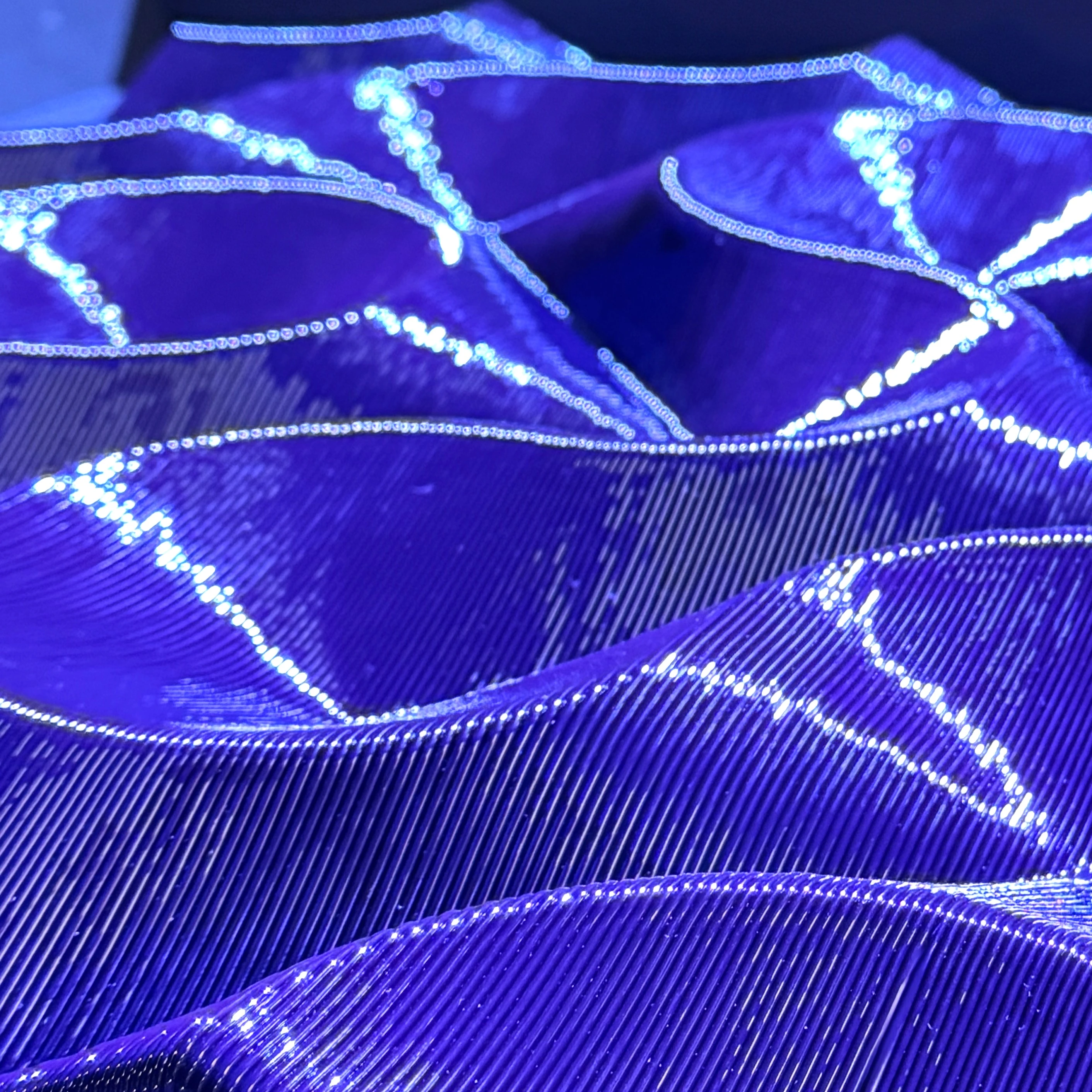

Colorful customization

RAW Idea offers a wide variety of colors, tailored to your needs. We achieve this by adding high-quality pigments to the material used for printing. This ensures the final product delivers a result that perfectly matches your preferences.

3D printing visions into reality

RAW Idea operates two advanced large-scale 3D printing systems, each designed for high-precision, industrial-grade manufacturing. A third system is currently in development, further expanding our capabilities. Read more about our printers below.

Let’s create something extraordinary together.

Contact usAR System Gantry

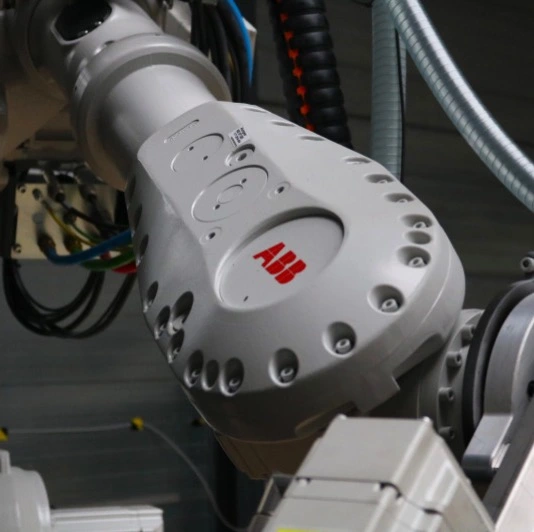

The AR System Gantry by RAW Idea is an advanced robotic 3D printing system, developed in

collaboration with Bloom Robotics. The setup combines an ABB IRB6650s industrial robotic arm with Bloom’s

S25 extruder kit, mounted on a 9-meter linear track, providing an impressive print area of 8 x 4 meters.

With an output of up to 25 kg per hour and support for various thermoplastic materials such as PP, PET-G, and other recycled polymers, we can produce large structures like the Silent Pod or Tanaruz Ozare boats.

RAW Idea also works with CEAD’s Flexbot technology and extruders. Thanks to CEAD’s robust extruder designs—with interchangeable nozzles (ranging from 2 mm to 24 mm) and extrusion capacities from 12 to 85 kg/hour—the system is suitable for a wide range of applications.

CEAD’s extruders are built for 24/7 production with a long service life. Safety software prevents damage to the robot or extruder through automatic print-stop and protection mechanisms. Additionally, multiple sensors and heating zones ensure precise material processing and high print quality as standard at RAW Idea.

ABB Robotics

RAW Idea utilizes an ABB IRB robotic arm with a custom

extruder. This setup is designed for high-precision, large-scale 3D printing. This industrial-grade system

has the payload capacity to support our custom high-performance extruder and a reach of over three meters in

width. The robot is mounted on a 12-meter track for an extended print area.

With this setup, RAW Idea produces large structures, such as 5-meter boats, in just three to four days. The combination of ABB’s proven reliability and our advanced extrusion technology enables fast, consistent, and high-quality production.

CEAD Solutions

RAW Idea takes large-scale 3D printed manufacturing to

the next level with the CEAD Flexbot. This hybrid system seamlessly combines robotic 3D printing and CNC

milling, allowing us to produce complex, high-precision parts with unmatched efficiency. Using CEAD’s pellet

extrusion technology, we work with strong, durable thermoplastic composites, ideal for large structures and

functional components.

Powered by a Comau robotic arm and a Siemens Sinumerik controller, the system ensures precise, multi-axis movement without the need for a separate robot controller. Its modular design allows for upgrades like heated worktables, high-throughput extruders, and expanded work volumes, giving us the flexibility to exceed the boundaries of additive manufacturing.

Our workflow

Advanced technology

By use of innovative 3D printing technology instead of other traditional methods we:

By leveraging cutting-edge 3D

printing

technology, we transform digital concepts into physical reality with precision, speed, and

unparalleled versatility. Our advanced design process enables us to achieve higher accuracy

and

enhanced quality control, all while significantly reducing production time.

This

approach boosts creativity and flexibility, allowing for custom, complex designs. At the

same time, our technology helps reduce harmful emissions and minimizes environmental impact,

making it a sustainable choice for the future.

Contact us

Ready to bring your ideas to life? Connect with us via the form below or on our social media channels!

R&D:

Anthonetta Kuijlstraat 48 3066 GS Rotterdam

Production:

Ringoven 32 6826 TR Arnhem

CoC:

77950283